Unlocking the Potential of Precision Engineering: Inside a China CNC Turning Part Factory

The modern industrial landscape is characterized by efficiency and innovation, particularly in the realm of CNC turning parts. One of the pivotal players in this industry is the China CNC turning part factory, which has become synonymous with cutting-edge technology and exceptional manufacturing capabilities. In this article, we delve deep into the intricate world of CNC turning, exploring why these factories are increasingly sought after for their precision and reliability.

The Essence of CNC Turning

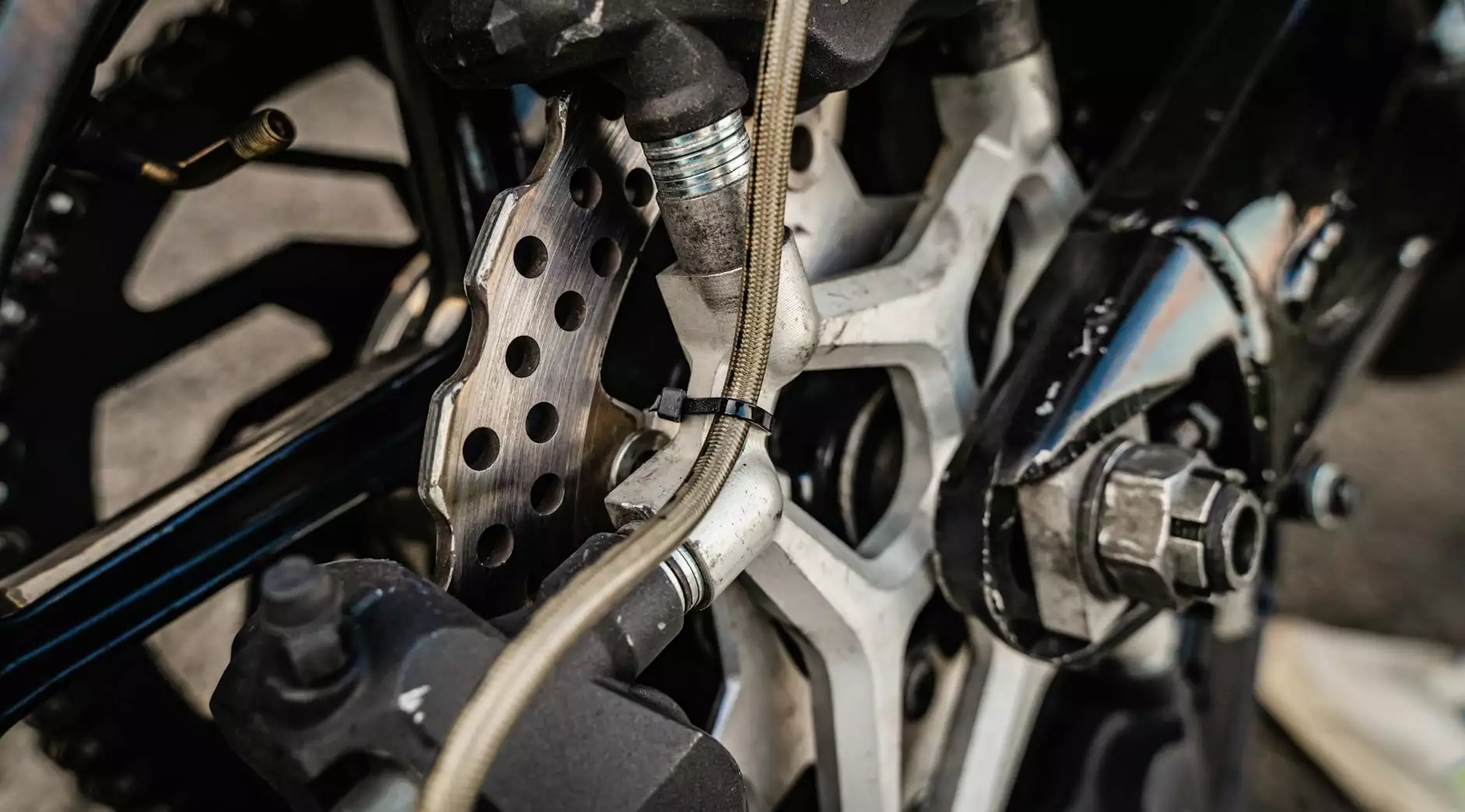

CNC turning is a manufacturing process where a piece of material, typically metal or plastic, is rotated against a cutting tool. This method is crucial for creating cylindrical parts with high precision. The automation aspect, utilizing computer numerical control (CNC), enhances the consistency and accuracy of each part produced. The process is vital for sectors such as automotive, aerospace, and consumer goods where precision and quality are paramount.

Advancements in CNC Technology

Over the years, CNC technology has undergone tremendous advancements that enhance the capabilities of a China CNC turning part factory. These advancements include:

- High-Speed Machining: Modern CNC machines operate at higher speeds, reducing production time and increasing efficiency.

- Improved Software Solutions: Innovative software allows for complex designs and programming, enabling factories to produce intricate parts with ease.

- State-of-the-Art Materials: Factories are now utilizing advanced materials that offer improved durability and performance.

- IoT Integration: The Internet of Things (IoT) technology allows for real-time monitoring and quality control throughout the manufacturing process.

Benefits of Partnering with a China CNC Turning Part Factory

Choosing a China CNC turning part factory for your manufacturing needs comes with a plethora of advantages. Here are some key benefits:

Cost-Effectiveness

One of the most significant advantages is the cost-effectiveness. With China being known for its competitive labor and material costs, businesses can save substantially while still receiving products of high quality.

Quality Assurance

Factories in China are increasingly adopting international quality standards such as ISO 9001, ensuring that the products meet robust quality requirements. This commitment to quality makes them a reliable choice for businesses globally.

Wide Range of Capabilities

China CNC turning part factories offer an extensive range of capabilities. From small precision components to large industrial parts, they can handle diverse manufacturing needs across several industries.

Rapid Production and Delivery

With advanced machinery and efficient production lines, these factories can accelerate the time from design to delivery, allowing businesses to meet tight deadlines.

Applications of CNC Turning Parts

The applications of CNC turning parts are vast and varied. Some notable industries that benefit from these components include:

- Automotive: Precision parts for engines, transmissions, and braking systems.

- Aerospace: Lightweight, durable components for aircraft and spacecraft.

- Consumer Electronics: Components for devices such as phones, tablets, and computers.

- Medical Devices: Specialized surgical instruments and diagnostic equipment.

Why Deep Mould is Your Go-To China CNC Turning Part Factory

At Deep Mould, we pride ourselves on being a top-tier China CNC turning part factory with a commitment to excellence and customer satisfaction. Here are several reasons why we stand out:

Expertise and Experience

With years of experience in the field, our team of engineers and technicians bring a wealth of knowledge and expertise to every project, ensuring that we meet and exceed client expectations.

Customized Solutions

We understand that every business has unique needs. At Deep Mould, we offer customized solutions tailored specifically to your project requirements, ensuring optimal results.

State-of-the-Art Facilities

Our factory is equipped with the latest CNC technology, allowing us to produce parts with exceptional precision and efficiency. This commitment to technology helps us stay ahead of the competition.

Sustainable Practices

Deep Mould is dedicated to sustainability. We employ eco-friendly manufacturing practices and materials to minimize our environmental footprint while providing high-quality products.

Quality Control Measures at Deep Mould

Quality assurance is at the heart of our operations. Our China CNC turning part factory implements several rigorous quality control measures, including:

- Comprehensive Testing: Each product is subjected to meticulous testing to ensure it meets stringent quality standards.

- Qualified Personnel: Our quality control team consists of highly trained professionals who conduct regular inspections.

- Customer Feedback Integration: We utilize customer feedback to constantly improve our processes and product offerings.

Conclusion: The Future of CNC Turning in Manufacturing

The future of manufacturing is bright, particularly for the China CNC turning part factory sector. With continued advancements in technology, a focus on sustainability, and an unwavering commitment to quality, companies like Deep Mould are well-positioned to lead in this exciting industry.

As businesses around the world continue to seek reliable, high-quality manufacturing partners, the role of China CNC turning part factories will only grow in significance. From cost savings to exceptional quality and rapid delivery times, the advantages of working with expert manufacturers are clear. Partnering with a trusted name like Deep Mould ensures that you stay ahead of the competition while meeting your manufacturing needs with precision and efficiency.